Applied DNA Sciences presents a special advertorial report on understanding how to determine if the products you make and sell are truly what they say they are

The entire issue of compliance standards for product components and labeling, sustainability claims and quality control in the home textiles industry has emerged as one of the most important aspects of the business over the past year.

As the industry has raced to adhere to these measures, there has been much confusion and and retailers and suppliers alike are grappling with how to comply to them.

In this special report, one of the leading third-party security and authentication services in the field, DNA Sciences, is seeking to set the record straight and provide credible information that will help companies in the business make informed business decisions.

Executives from the company prepared this informational guide to the subject of premium verification and authentication.

How do you know if your product claims are 100% Pure Egyptian Cotton?

Consumers rely on brands they trust to ensure the products they buy are what they say they are. Brands are contracting with many supply chain partners to deliver on the claims they establish for the products they bring to. A good example and common misperception in today’s textile world is that Egyptian cotton is one of the best. Consumers buying sheets made of Egyptian cotton expect a luxurious night of sleep because of the association with presumed premium quality.

Labeling and Claims

Government agencies like the Federal Trade Commission established clear guidelines to protect the consumer by ensuring that products are based on accurate information on product origin, construction, quality and care. The disclosure of fiber content is integral to trade in textiles and apparel; it is incumbent upon the brand and its supply chain partners to know, and to correctly report, fiber content in both documentation and on product labels. If a product is labeled to use a single fiber such as 100% Egyptian ELS (extra long staple), there is no tolerance for the use of any other fiber type.

Amplifying the industry issue

In 2012 global cotton prices rose to record levels, especially for premium Pima ELS cottons. Historically, the goal of select processors of premium cotton fibers (e.g. Egyptian ELS or American Pima) was to buy the highest quality cotton at the lowest price, attempting to meet product specifications by blending bales with different fiber qualities and types. Blending of premium extra long staple cotton with shorter staple non-ELS upland cotton occurs when manufacturers search for higher profit margins and there is a shortage of available high-quality ELS fiber. This blending of different fiber types results in impure products being labeled and sold as 100% ELS cotton, violating U.S. and international laws.

Validation by Proprietary Technology

Within the home textile industry, retailers and brands have relied on documentation and other forms of inspection that provide no clear confirmation as to the fiber content of the finished labeled product. Working with cotton trade associations, Applied DNA Sciences (ADNAS) validated (and commercialized) the methodology to identify the genetic variations between Pima cotton (G. barbadense) and Upland Cotton (G. hirsutum). This proprietary technology, which is setting new industry standards, is known as fiberTyping® and is available to the cotton industry today. fiberTyping® offers a diagnostic DNA test that can help verify fiber content and assure quality and label compliance. It provides a forensic method of authentication for Pima cotton products but does not provide country of origin at this time. ELS products can include: American Pima, Egyptian Giza, Australian ELS, Chinese ELS, Peruvian Pima, Brazilian ELS, Indian Suvin, and many other Pima products that contain the G. barbadense native DNA. Applied DNA Sciences is collaborating with USDA to provide future genotyping that may discriminate between cotton cultivars (such as Egyptian Giza 88 vs Giza 86).

Our research shows the falsehoods of claims being made

Applied DNA Sciences in 2009 conducted a market sweep of 100% ELS- or 100% Pima-labeled bed linens, using its patent protected fiberTyping® to confirm the fiber content. In this study, 29 samples were selected at random in a market sweep of products from multiple U.S.-based luxury retail outlets and online websites. fiberTyping® test results indicated that non-compliance occurred in almost every sample submitted:

- 89% of all sheeting surveyed was non-compliant

- 48% of all sheeting was made primarily of Upland

- 41% of all sheeting was made of a Blend of Upland and ELS

- About 40% of all sheeting made in China contains Upland or a Blend

Since this initial testing, ADNAS has processed thousands of tests for many brands, manufacturers and other cotton supply chain partners. The results have consistently shown a very high level of blending throughout the supply chain.

What is the current state of Egyptian cotton fiber?

According to the USDA’s Gain Report (March 30, 2015), poor management of seed stocks has greatly reduced the quality and supply of Egyptian Giza 88 and Giza 86. Both are used to manufacture home textile and apparel, with very high yarn counts. In some cases it has been found that Giza 86 is no longer capable of meeting high yarn counts, and therefore is a less reliable fiber to manufacture fine linens.

Due to deteriorating quality (USDA Gain Report March 30, 2015), the supply of Giza cotton has been drastically reduced over the past few years, begging the question: has the quantity of Egyptian cotton finished goods similarly diminished?

Specifically, Cotton Institute of Research Giza-Egypt findings cannot be validated

The Cotton Research Institute of Giza-Egypt presented its point of view “Developing a DNA-based Technology for Identifying the Presence of Egyptian Cotton Fibers for Various Textile Products” (ICA Bremen Cotton Conference 2016).

They claimed to use an “internal DNA test” to determine if a cotton product contains G. barbadense or G. hirsutum or G. arboreum (Indian), or a blend.

Specifically, it was claimed that the evidence is based on nuclear DNA, which is known to be either missing, or degraded beyond resolution in mature cotton fiber. In fact extraction efficiency of DNA material from fiber using the widely used CTAB (cetyltrimethylammonium bromide) extraction method with subsequent DNA precipitation, relied on cotton fibers being raw, i.e. not washed (read scoured) or wet treated in any way, and there being seed material contained within the specimen. (Gordon, S., 2009, in “Identification of Textile Fibers”).

Nuclear DNA is not intact in the Mature Cotton

Cotton fibers start to mature around 45 to 60 “Days Post Anthesis” (DPA), and fibers start dying sometime after 40 DPA. When a cotton cell dies, the DNA becomes fragmented and degraded, making it far more difficult to analyse by the polymerase chain reaction (a technology used to duplicate a few copies of DNA to over hundreds of millions of copies of a particular DNA sequence). Nuclear DNA is nearly completely degraded after 45 DPA, making any claims for nuclear DNA analysis using mature cotton fibers, yarns, or fabrics very difficult except in the hands of experts who are experienced in the reconstitution of degraded DNA [Source: “A study of programmed cell death in cotton (Gossypium hirsutum) fiber”, Meghan C. Roche, 2007, Texas A&M University.]

In 2009 ADNAS discovered the survival of chloroplast DNA in mature cotton fibers for its fiberTyping® DNA assay.

The Answer

ADNAS has a solution that uses forensic science to tag, type and test textile products. Trademarked as SigNature® T for textiles, the core technology has a unique molecular tag that marks cotton fibers en masse in the gin that are checked at every step of the supply chain, as the fibers are converted into yarn, fabric and finished goods. In addition to SigNature T, all cotton is fiberTyped®, which quantifies the native DNA by species.

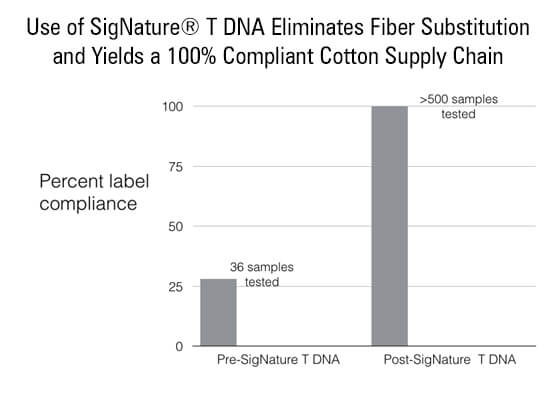

As shown in the accompanying figure, once SigNature DNA tagging was implemented, including the strict storage and labeling protocols, along with inspections and frequent DNA testing, the level of DNA compliance rose quickly to 100%. Data was obtained by APDN from commercial samples.

A patented, cloud-based IT framework, known as “digitalDNA®” tracks the integrity of the marked cotton from “Dirt to Shirt”, until finished goods are DNA-verified and delivered for retail. The technology enables consumers to have a transparent sense of where their product comes from.

Honest Cotton. DNA Testing = Truth

Bottom-line, consumers will buy products from sources they trust. Retailers and brands will buy from suppliers that provide “truthful” materials. Suppliers will need tools that provide them with certainty that the yarns they use are really what they claim to be. DNA technology can help everyone in the supply chain, but it needs to be done precisely, using methods that are validated on textiles and with trusted and trustworthy organizations within the industry.

The story behind Egyptian cotton and the “Egyptian Gold Seal” recently awarded to manufacturers needs to be seriously questioned by brands, supply chain partners and ultimately the consumer. The Applied DNA Sciences promise to our customers is to Make Life Real and Safe, so we take it to heart to ensure the true story is being told based on facts and documented results.